Efficient On-Site Steel Reinforcement Installation for Quick and Reliable Builds

Efficient On-Site Steel Reinforcement Installation for Quick and Reliable Builds

Blog Article

Enhance Building Performance With Specialist Steel Correcting

In the world of construction, the role of expert steel dealing with can not be overstated, as it straight affects both the architectural stability and effectiveness of tasks. Skilled steel fixers apply their proficiency to make sure specific positioning and safe and secure connecting of reinforcements, which is essential in enhancing and decreasing pricey errors product use.

Importance of Steel Correcting

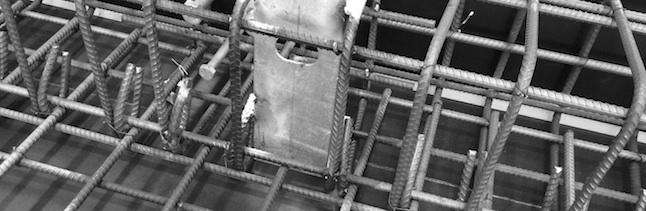

Why is steel dealing with a crucial component in building and construction? Steel repairing entails the positioning and securing of steel reinforcement bars (rebars) within concrete frameworks, ensuring architectural integrity and toughness. This process is important in giving tensile toughness to concrete, which naturally lacks this property. Without proper steel taking care of, frameworks are at threat of failure under numerous lots, consisting of shear, tension, and compression.

Moreover, the accuracy involved in steel dealing with straight affects the total top quality of construction. Exact positioning of rebars makes certain that layouts are adhered to, minimizing the threat of structural weak points. In addition, steel dealing with adds to the reliable transfer of loads within a framework, permitting the construction of more secure and much more resilient buildings.

Along with boosting architectural efficiency, steel repairing also plays a role in enhancing construction timelines. By making certain that steel support is properly positioned before concrete is poured, the threat of rework is significantly minimized. This structured method not only conserves time but likewise reduces total project prices. Therefore, understanding the significance of steel dealing with is essential for professionals in the building and construction industry, as it creates the backbone of enduring and safe frameworks.

Advantages of Expert Proficiency

Additionally, knowledgeable steel fixers are adept at translating building and design plans. Their ability to accurately translate layouts right into useful applications minimizes errors, thereby lowering costly rework and task hold-ups. Professional know-how likewise adds to improved safety on site. Experienced steel fixers are learnt sector requirements and finest techniques, which assist to alleviate risks related to steel job.

In addition, making use of expert solutions can bring about much more efficient use products. Professionals can optimize the quantity of steel required, thus reducing material costs and reducing waste. This efficiency not just benefits the budget plan but also lines up with lasting building and construction methods.

Lastly, depending on professional experience cultivates a collaborative environment among designers, contractors, and designers, advertising smooth communication and task implementation. On the whole, the benefits of professional proficiency in steel taking care of are very useful, dramatically affecting the success and quality of building projects.

Techniques for Effective Steel Mending

Effective steel dealing with methods are essential for ensuring prompt project conclusion and optimum structural efficiency. One of the foremost techniques involves accurate planning and design of rebar placements based on structural illustrations. Making use of advanced software program for 3D modeling can promote much better visualization and coordination amongst the task group, minimizing errors throughout setup.

In addition, using proper securing methods, such as wire linking or mechanical couplers, can improve joint honesty and lower labor time. Educating workers in best practices for security and effectiveness is also vital, as experienced workers can perform jobs quicker and properly.

Last but not least, normal assessments during the setup process can help identify and rectify possible problems early, preventing pricey delays. By integrating these methods, building and construction projects can achieve improved efficiency and enhanced architectural quality, inevitably providing better outcomes for stakeholders and clients.

Common Challenges and Solutions

While executing effective techniques can significantly boost steel repairing procedures, various obstacles often emerge that can hamper progress. One typical difficulty is the miscommunication between groups, resulting in mistakes in steel placement and enhanced rework. To address this, establishing clear interaction procedures and utilizing sophisticated software for sychronisation can improve precision and teamwork.

Another considerable concern is the irregularity in website problems. Unanticipated aspects such as weather condition adjustments or ground instability can interrupt steel repairing operations. A positive solution entails performing complete website analyses and having backup plans in position to mitigate prospective delays.

In addition, labor shortages can prevent the prompt conclusion of look at this now steel taking care of tasks. Purchasing training programs and cultivating a culture of skill development amongst employees can assist bridge this gap.

Finally, inadequate safety and security More hints steps can pose threats to both workers and the job timeline. Implementing strict safety and security procedures and regular training sessions can enhance employee safety and reduce accident-related disturbances. By identifying these obstacles and applying reliable remedies, construction specialists can guarantee a much more efficient and reputable steel taking care of process, ultimately causing effective job results.

Effect on Task Timelines

The influence of steel choosing task timelines is an important factor to consider for building and construction professionals. Reliable steel taking care of directly influences the general timetable, as delays in this phase can result in significant troubles in subsequent building and construction activities. Effectively implemented steel taking care of guarantees that the structural stability of the project is accomplished in a timely fashion, promoting a smooth change to the next phases of construction.

When steel taking care of is executed by proficient experts, the danger of mistakes and remodel is lessened, promoting adherence to the prepared timeline. Conversely, below average steel dealing with can result in pricey delays, needing added time for improvements and examinations. The assimilation of sophisticated techniques and modern technologies in steel repairing, such as 3D modeling and prefabrication, can further enhance performance, permitting quicker setup and reduced labor expenses.

Furthermore, timely conclusion of steel repairing effects the scheduling of various other professions, such as concrete ending up and putting work. steel fixing. By prioritizing specialist steel fixing, construction teams can successfully manage their timelines, guaranteeing web link jobs are supplied on schedule and within budget plan. Eventually, purchasing top quality steel repairing solutions is vital for keeping job momentum and achieving effective end results

Final Thought

To conclude, professional steel taking care of plays an important function in improving building and construction effectiveness by ensuring the precise placement and protected tying of steel supports. The fostering of innovative strategies, such as 3D modeling, improves the installment procedure, decreasing mistakes and revamp. Partnership amongst professionals, engineers, and designers even more reinforces job end results, inevitably adding to the structural integrity and durability of concrete structures. Focusing on expert experience in steel fixing is essential for the success of building and construction jobs.

Steel fixing involves the placement and protecting of steel reinforcement bars (rebars) within concrete frameworks, guaranteeing architectural stability and durability. Proficient steel fixers are trained in industry standards and ideal practices, which aid to mitigate threats linked with steel work.

By acknowledging these obstacles and applying reliable services, building and construction professionals can guarantee an extra effective and trustworthy steel dealing with procedure, ultimately leading to successful job end results. (steel fixing)

By prioritizing expert steel dealing with, building and construction teams can successfully handle their timelines, making certain projects are delivered on routine and within spending plan.In final thought, specialist steel repairing plays an essential function in improving construction effectiveness by making sure the precise positioning and secure connecting of steel supports.

Report this page