How On-Site Steel Reinforcement Installation Helps Meet Building Codes

How On-Site Steel Reinforcement Installation Helps Meet Building Codes

Blog Article

Mastering Steel Repairing: Techniques for Superior Building And Construction

Understanding steel repairing is an essential element of construction that directly affects the security and durability of concrete frameworks. By recognizing the intricacies of accurate placement, the ideal usage of tools, and common risks to stay clear of, specialists can substantially enhance overall project end results. Additionally, sticking to ideal security practices not only safeguards workers however likewise adds to the honesty of the structure itself. As we explore these techniques in higher information, the implications of understanding this essential ability become significantly noticeable, increasing questions about how these techniques can transform construction methods.

Comprehending Steel Correcting Essentials

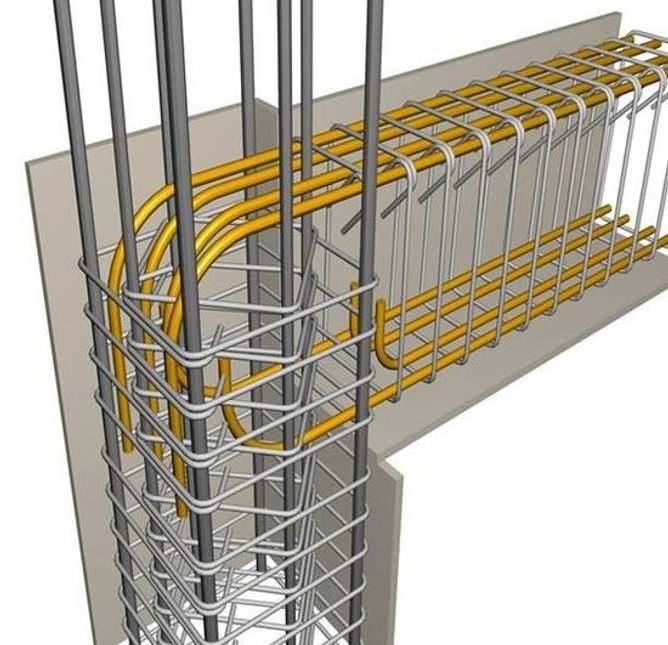

Steel dealing with, a necessary component in the construction industry, entails the positioning and securing of steel reinforcement bars (rebar) within concrete structures. This procedure is important for making sure the structural stability and durability of concrete components, as rebar significantly enhances tensile toughness, which concrete does not have.

Comprehending the fundamentals of steel taking care of begins with acknowledging the various types of rebar and their requirements, consisting of size, quality, and finish. Rebar is generally made from carbon steel and is available in various dimensions, which are picked based on the structural demands of the task.

Additionally, using ideal washing lengths and anchorage methods contributes to the general security of the concrete structure. It is vital for steel fixers to comply with safety criteria and best methods throughout the installment procedure, making sure not only the success of the project however also the safety of all personnel included.

Vital Tools and Equipment

Successful steel fixing relies heavily on the right devices and devices to make sure precision and effectiveness in the setup process. Key devices consist of rebar cutters, which are important for making precise cuts in various sizes of steel bars, and rebar benders that supply the essential angles for correct placement. In addition, a top quality set of pliers, specifically tie cord pliers, is vital for securing rebar with tie cord.

Determining tools, such as tape actions and laser degrees, facilitate precise layout and placement, while a robust selection of clamps and vises help in holding the rebar ready during assembly. Safety and security equipment, including goggles and gloves, can not be forgotten, as they safeguard workers from prospective threats connected with steel handling.

For larger jobs, purchasing mechanical tools like rebar linking devices can significantly improve performance. Correct storage options, such as containers or shelfs, help organize products and preserve a risk-free functioning environment - steel fixing. By using these vital tools and tools, steel fixers can boost their operations, making sure that architectural integrity and construction timelines are fulfilled with accuracy

Strategies for Accurate Placement

One effective approach is the use of templates or noting guides to develop accurate places for steel bars. These overviews must be made from these details long lasting materials to hold up against the roughness of construction and need to be examined against architectural drawings to confirm precision. In addition, employing laser degrees can considerably boost positioning and elevation accuracy.

Moreover, maintaining appropriate spacing in between supports is essential. This can be accomplished by utilizing spacers or chairs that are made to hold steel bars in position at the required range from the formwork.

Regular assessments throughout placement must be conducted to make certain conformity with project specs. Any type of deviations have to be resolved instantly to avoid structural weak points.

Lastly, partnership with other trades is essential, as clear communication can stop positioning mistakes that may occur from conflicting building activities. By carrying out these strategies, steel fixers can considerably add to the total quality and safety of the building job.

Typical Blunders to Avoid

While ensuring the appropriate placement of reinforcement steel is important, numerous typical mistakes can undermine the integrity of the building procedure. One frequent mistake is insufficient spacing in between steel bars. Insufficient spacing can lead to blockage, which can endanger concrete circulation and bonding, inevitably influencing structural toughness.

An additional typical error involves ignoring to click for source appropriately protect the reinforcement bars throughout positioning. Failure to adequately support the steel or connect can lead to misalignment, particularly when concrete is poured, resulting in structural weaknesses. Additionally, ignoring the required cover density frequently leads to premature deterioration of the steel, decreasing the long life of the structure.

Improper cutting and bending of rebar is an additional risk that can cause tension and compression concerns within the concrete. It is important to comply with specific requirements to maintain the intended load-bearing ability.

Last but not least, poor evaluation before concrete pouring can enable these errors to go unnoticed. Normal checks and adherence to create requirements are necessary to make sure that steel dealing with is done correctly. By preventing these usual errors, construction professionals can enhance the sturdiness and security of their jobs, ensuring an effective end result.

Ideal Practices for Security

Making certain the honesty of steel repairing is not just regarding staying clear of common errors but also regarding carrying out finest methods for safety and security on the building site. A detailed safety and security plan ought to begin with appropriate training and orientation for all personnel associated with steel taking care of. Workers have to be acquainted with safety and security methods, tools use, and emergency treatments to minimize risks effectively.

Keeping a orderly and clean work environment is just as crucial. Clear paths and proper storage space of materials can substantially reduce trip and loss dangers. Moreover, implementing durable communication protocols, such as hand signals or radios, can prevent mishaps created by miscommunication.

Last but not least, promoting a culture of safety among staff member urges watchfulness and responsibility. Regular safety meetings and seminars regarding prospective threats will advertise proactive measures and enhance general safety and security on the building website. By sticking to these best practices, the risk of mishaps during steel fixing he said jobs can be significantly minimized.

Verdict

Understanding steel dealing with is vital for ensuring the architectural integrity and resilience of concrete constructions. By using exact techniques, using appropriate devices, and adhering to ideal practices, the top quality of building can be significantly improved.

Grasping steel dealing with is an essential facet of construction that directly influences the stability and longevity of concrete structures. By making use of these essential tools and devices, steel fixers can improve their process, ensuring that structural stability and building and construction timelines are fulfilled with accuracy.

While ensuring the correct placement of support steel is critical, a number of common blunders can weaken the stability of the building and construction procedure.Making certain the stability of steel dealing with is not just concerning staying clear of common mistakes but additionally regarding executing ideal methods for safety and security on the building website.Understanding steel repairing is crucial for making sure the structural stability and sturdiness of concrete building and constructions.

Report this page